Separate the rest from the best- We mean it!

Not all 3pl Fulfillment companies excel at what they do….

We specialize in knowing the product we are receiving, storing, picking and packing.

Precision

It all begins with precision. That’s why we measure every new product that arrives to our fulfillment center. We don’t take chances.

From irregular-shaped parts and components to small and large boxes and case-pack items, our measuring systems offer unprecedented precision for all of your planning needs. Step away from the frustrating tape measure and instead embrace a simpler, more effective approaching to capturing information and translating it into actionable insights about everything from storage space planning to carton size selection.

Bad cube data is expensive. By capturing the product size and weight data, we are able to eliminate bad data resulting in improved profits for your business.

Storage efficiency

Every product is different, and that is why we have different storage profiles for your products. We want to make sure your product is captively stored, minimizing any damage to your product. It should be easily retrievable and shouldn’t get lost in the warehouse.

We analyze product dimensions and velocity

Organize inventory strategically

Establish picking process

Maintain accurate inventory data

Analyze error data

Automate all repetitive processes

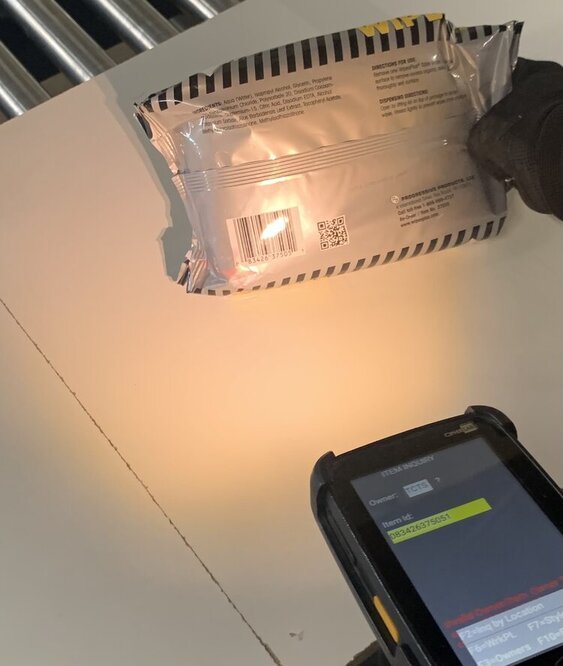

Picking Accuracy

It continues with picking accuracy. That’s why we make sure every product is scanned at the time of picking. We don’t rely on messy old fashioned ways of printing a paper ticket and passing it on to our picking team.

Analyze product velocity

Organize inventory strategically

Establish picking routes

Maintain accurate inventory data

Verifying that all items are in proper slots/locations and properly labeled

Store different items/parts in separate storage bins (items stored together in a single bin leads to picking errors)

Make sure that every picked product is scanned at the time of picking

Presentation

The next and last step is presentation. When a package leaves our facility on the way to your customer, it’s got to look great! No excuses!!

Without the over-taped look of many cases today, presentation of cases sealed with an automated package sealing machine is enhanced, making your presentation much more professional looking.

When you use staples, glue, or hand taping to seal cases during packaging, there is a much higher probability of damage to your products.

When we ship a carton, it is always taped by machine and never taped by hand —> unless you want us to :-)